DRI PLANT (using the global method of midrex)

The plant consists of three production units with two units, I and II, having a production capacity of 1,100,000 tonnes per year of sponge iron (DRI). These units commenced commercial operations on March 28, 1990.

The third unit, with a production capacity of 650,000 tonnes per year of hot briquetted iron (HBI), entered the commercial operation stage on November 13, 1997. The total design production capacity of the direct reduction plant is 1,750,000 tonnes per year.

STEEL PLANTS

Steel Plant No. 1

- Commenced commercial operation on October 16, 1989, with an annual design capacity of 670,000 tons of liquid steel for producing 630,000 tons of billets and blooms.

- In 2008, the plant underwent an expansion, increasing its annual designed capacity to approximately 1,060,000 tons.

- The plant operates with three electric arc furnaces, each with a capacity of 90 tons.

Steel Plant No. 2

- Began commercial operations in 1991, with an annual design production capacity of 650,000 tons of liquid steel to produce 611,000 tons of slabs per year.

- Utilizes three electric arc furnaces, each with a capacity of 90 tons.

BARS AND ROD MILL

The plant has two lines to produce bars with a designed capacity of 400,000 tons of bars. The first line was commissioned on 12.10.1988, and the second line on 18/02/1989. In 1997, a double strand line was implemented, with an annual designed capacity of 400,000 tons, which started operation on 27/05/1998.

Additionally, the Light and Medium Sections Mill entered the stage of commercial operation on 08/04/1989 with an annual designed production capacity of 120,000 tons of light and medium sections in various sizes and dimensions.

LIGHT AND MEDIUM SECTIONS MILL

HOT STRIP MILL

The manufacturing facility was designed with an annual production capacity of 580,000 tons of hot-rolled coils and became operational on May 10, 1989.

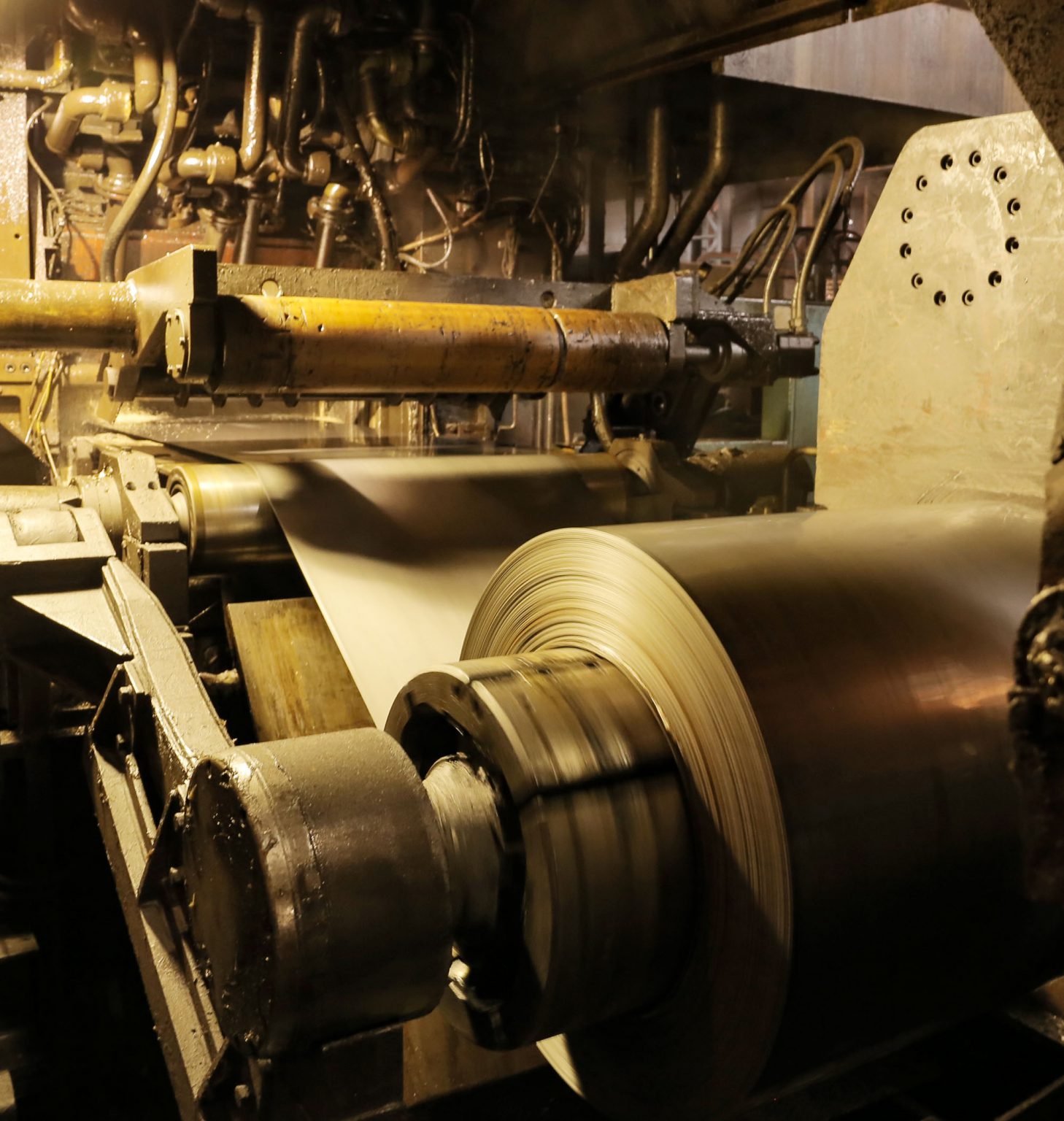

COLD STRIP MILL

commenced its commercial operations on January 20, 1990, with an annual design production capacity of 140,000 tons of cold-rolled coils.

GALVANIZING AND PAINT COATED LINES

In order to expand the company’s product portfolio, enhance quality, and boost production capacity, one of the expansion projects entailed the installation of a galvanized coil line with an annual capacity of 80,000 tons. Additionally, on September 2, 1998, a painted coil line with a planned yearly production capacity of 40,000 tons began commercial operations.

LIME AND DOLOMITE PLANT

The company’s plants are supplied with limestone and dolomite from the Sedada quarry, located 140 kilometers east of Misrata. The quarry has an annual production capacity of 88,000 tons and processes the raw materials to the required sizes.

New Bar Mill Plant

In June 2017, a single bar production line was set up at the plant. The production line was designed to produce 800 thousand tons of different bar sizes (8-40 mm) annually. It uses billets of 130 mm to 150 mm in size. It is worth noting that all operations and tests were carried out by Libyan teams.